|

Lin'an Longshine Imp.& Exp. Co., Ltd.

|

Gold Index: 44238

You are here: home > Wire and Cable Equipment Accessories > Rolling Ring Drive > Winding parts linear traverse

Winding parts linear traverse

| Price: | 60.0~200.0 USD |

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Model No.:

LS-R121

Production Capacity:

10,000 sets / month

Delivery Date:

It depends on client's QTY

Brand Name:

GP3

Application 1:

Wire, Cable and Fiber optic...

Application 3:

Spraying Equipment and Spra...

Application 5:

Packaging Equipment and Con...

Means of Transport:

Ocean,Land,Air

Packing:

We can packaging it accordi...

Part:

Transmission Gear

OEM No.:

LS

Application 2:

Scanning Equipment and Scan...

Application 4:

Slitter Rewinders

Type:

Type-A ,Type-B,Type-C

The polished shaft rolling ring traverse drive can make the wire or cable welding wire in perfect order with easy-maintenance.

Description :

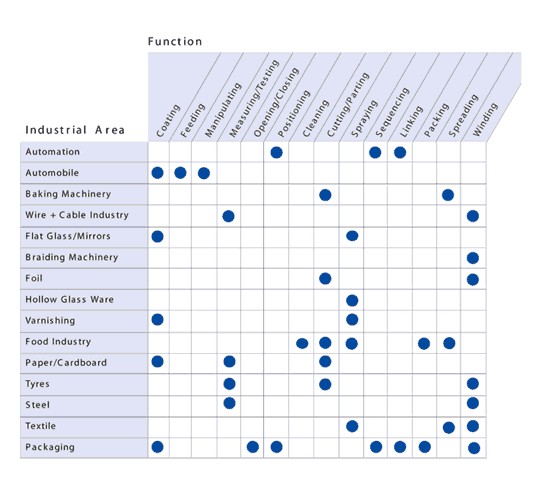

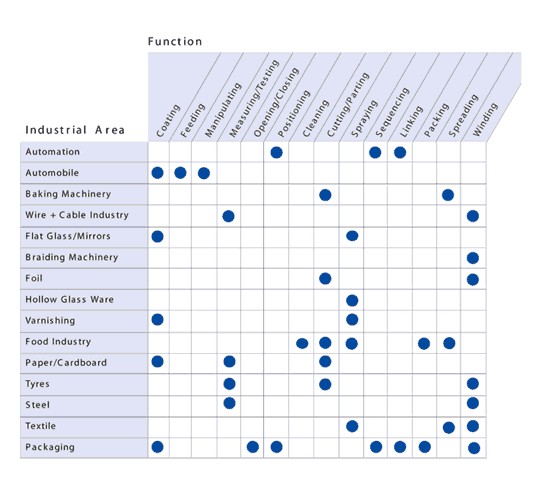

The GP rolling ring drive assembly is uniquely suited for Wire, Cable and Fiber optic Level Winding system, Scanning Equipment and Scanning Machinery , Spraying Equipment and Spraying Machinery, Slitter Rewinders , Packaging Equipment and Converting Machinery

The GP rolling ring drive assembly is uniquely suited for Wire, Cable and Fiber optic Level Winding system, Scanning Equipment and Scanning Machinery , Spraying Equipment and Spraying Machinery, Slitter Rewinders , Packaging Equipment and Converting Machinery

The linear speed (pitch) of the traverse and the travel direction are both mechanically controlled -independently of the drive motor. This eliminates the need for electronics and programming to save money and simplify set-up and operation.

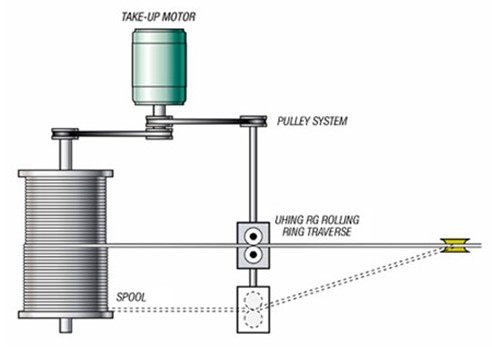

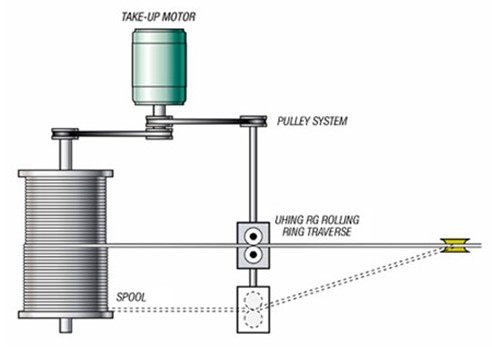

A GP traverse winding assembly does not require a separate drive motor. Instead, the GP shaft is linked via a simple pulley system to the take-up spool shaft.Once the linear pitch is set on the GP traverse winding unit, it remains automatically synchronized with the rotating spool, even if the take-up motor speeds up or slows down. There is never a need to change gears or reverse the motor.

System Showing :

The GP rolling ring traverse winding set up eliminates the need for additional controls and electronics.

The GP rolling ring traverse winding set up eliminates the need for additional controls and electronics.

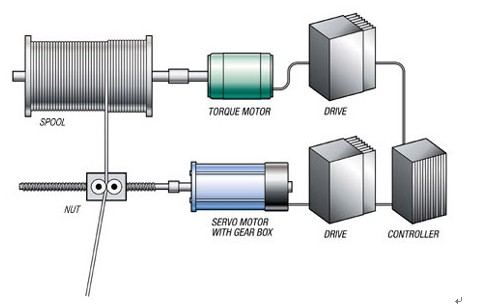

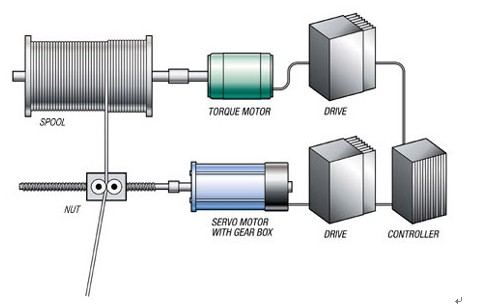

A typical screw-based winding system requires costly extras such as controllers and servomotors

Application :

How it works :

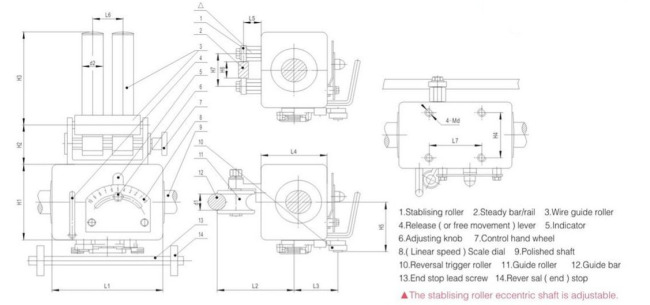

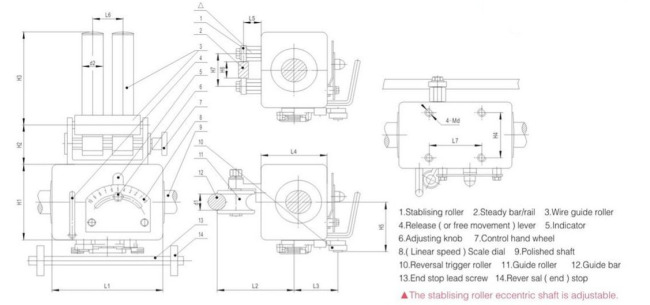

At present , we have GP3 A type , GP3 B type and GP3 C type which have different functions .

GP3 A type & GP3 B type

Advantages :

Stepless AdjustmentThe take-up reel transfers a certan speed to the polished shaft.Without changing the roatating speed of the shaft though move the indicator on the scale dial,adjust the traverse drive's speed of reciprocating motion on the shaft,range from 0 to the maximum pitch setting.

Application :

How it works :

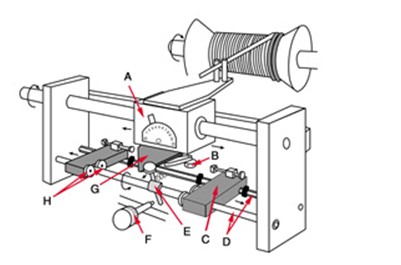

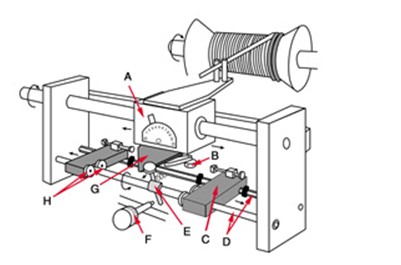

The end stop assemblies (C) are mounted on two shafts called guide rails (D). The front most shaft is fitted with the end stop ratchet lever (E). A cam (G), affixed to the rolling ring drive (A), is positioned so the ratchet lever is actuated each time the drive passes by. When the lever is actuated, the front shaft rotates relative to an adjustable value, which is preset using the control knob (F). As the shaft turns, it bears against the bearings (H) mounted on the end stop assemblies. The bearings are pressed against the smooth shaft and function like a screw to move the end stop assemblies apart. As the end stops - which trigger the reversal mechanism (B) -- move apart, the required increase in stroke length is achieved. When the spool is filled, the assembly is easily reset by hand.

At present , we have GP3 A type , GP3 B type and GP3 C type which have different functions .

GP3 A type & GP3 B type

Advantages :

Stepless AdjustmentThe take-up reel transfers a certan speed to the polished shaft.Without changing the roatating speed of the shaft though move the indicator on the scale dial,adjust the traverse drive's speed of reciprocating motion on the shaft,range from 0 to the maximum pitch setting.

Instantaneous Reversal With no need to change the shaft speed of rotation,when rhe reversal trigger roller contacts the end stop,the travel direction of the traverse drive will be pivoter to its mirror direction with reversal time of not more than I second.

High Traverse SpeedThe traverse drive speed of linear motion on the shaft can be up to 0.4m/sec.max..,and the applicable speed is Usually 0.3m/sec. So it can meet the requirement of some situations for high traverse speed and very frequent reversal.

Release Assembly The traverse drive features the release system..It allows the rolling rings to disengage from the shaft without the shutdown and so can be manually moved at any position on the shaft.It can traverse from the end part.

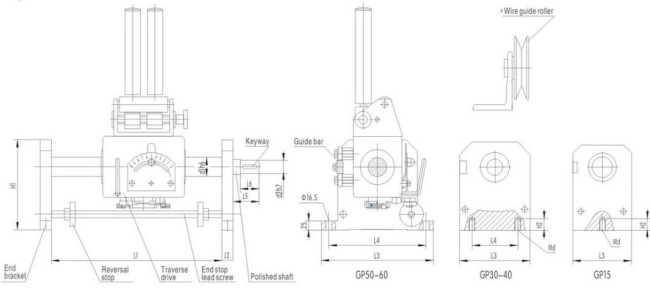

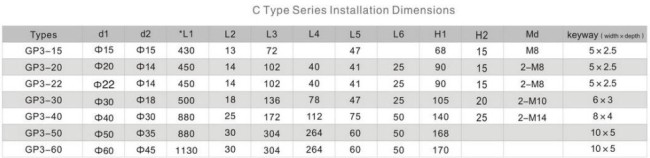

Installation instruction :

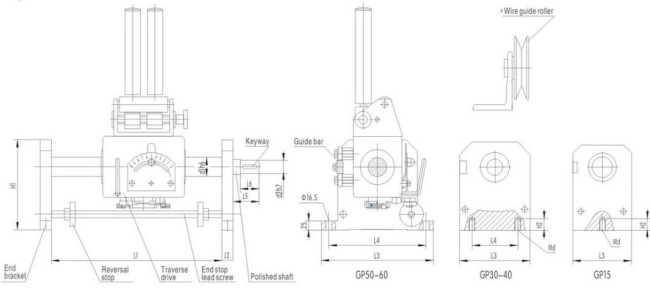

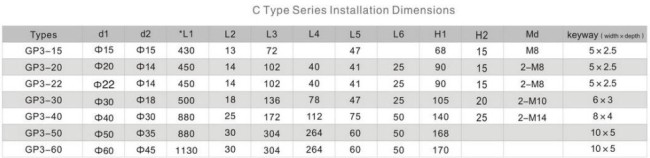

It is important to prepare the polished shaft ,the guide bar,the end stop leda screw,the end stops,etc.according to the installation dimensions of relative types and the technical requirements of equipment,as the figure shows.

Polished Shaft Surface hardness:HRC50-60;Tolerance on diameter:h6;True running tolerance:<0.1mm/m;Length:not larger than 20-30 times of the diameter of the shaft;Leading end chamfer:2x30°.

Ratio of take-up reel and the shaft in general,the shaft speed should be smaller than the take-up reel speed so that the shaft and traverse drive lives could be increased.It is recommerded that the rotation ratio of the shaft over the take-up reel be1:1-1:5,with lower ratio for thicker wires and higher ratio for thinner wires,and the scale indication not being less than1.

Direction of Shaft Rotation the rotation direction of the shaft transmitted by the take-up reel may be eitter positive or negative,however,there is difference regarding the installation positons of the reversal arm,or otherwise the direction could not be switched.When facing the scale dial, downward rotation is defined as positive.The reversal may be realized only when the trigger roller is installed backward.The shaft rotation is presetted and installed as in positive direction at the factory.

GP3 C type

GP3 C type

Advantages and Installationin struction :

The maintenance is mainly performed for three purposes:achieving instantaneous reversal,constant reciprocating pitch and adequate side thrust.

Reversal Points To keep symmetrical the angles of the fixed arm and the movable arm ,torsion springs shall be kept preese between the fixed and movable springs.The spring shall be replaced in case of inadequate pressure.

Traverse Thrusr The thrust is mainly dependent on the adjustable nuts and the pressure of disk spring. On the bottom of the traverse housing there is one or two nuts that can be adjusted. When adjusting the pressure,attertions shall be paid that certain clearance be allowed between the Polished Shaft and the sealing covers on adjusted as too tight a thrust may prevent the Polished Shaft fromreversing. So in case of the traverse thrust required is met,adequate thrust will incease the lives of the Polished Shaft and the traverse housing.

Pitch Adjustment the travers housing might travel asymmetrically on the shaft,because of the difference of positive and negative angles of the eccentric shaft and the housing.The asymmentry problem can be solved by loosing the two set screws on both sides of the scale dial arld a slight left or right tuning for adjusting the symmetrical position of eccentric shaft and housing.

Maintenance it is necessarry to keep a film of lubriction of the shaft and the reversal mechanism to promote the operational lifte of the shaft and the drive assembly.

Packaging & Shipping way :

Certification :

Packaging & Shipping way :

Certification :

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

Lin'an Longshine Imp.& Exp. Co., Ltd. [China (Mainland)]

Business Type:Manufacturer, Trading Company

City: Hangzhou

Province/State: Zhejiang

Country/Region: China (Mainland)

You May Like:

Product (507)

- Solar Power System (1)

- Cable Raw Materials (134)

- Wire and Cable Equipment Accessories (192)

- Ceramic Parts (180)